Understanding Diesel Fuel Contamination: Causes, Identification, and Prevention

Diesel fuel is a stable and reliable energy source when properly stored and maintained. However, contamination remains a common challenge for equipment owners, bulk fuel users, and standby power operators.

Among the most misunderstood forms of contamination is bacterial growth, often incorrectly blamed for a wide range of fuel quality issues.Understanding the causes, conditions, and proper treatment options is essential to maintaining reliable fuel systems.

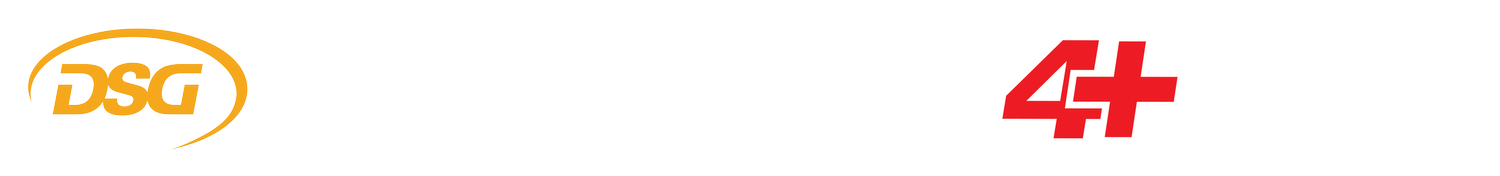

Dark spots in diesel fuel are bacterial growth that is preventable with proper care and maintenance

Bacterial growth in diesel fuel is more accurately described as microbial contamination. Microorganisms such as bacteria and fungi do not live in the fuel itself; instead, they thrive at the interface between fuel and water. Water enters diesel systems through condensation, leaking tank fittings, poor housekeeping, or contaminated fuel deliveries. Once water is present, microbes use hydrocarbons in the fuel as an energy source, multiplying rapidly and forming biomass, sludge, and acidic byproducts.

Bacterial Growth separated with filter

Microbial contamination is most encountered in bulk storage tanks, standby generator systems, marine applications, and low-turnover fuel systems. Warm temperatures, prolonged storage, infrequent fuel movement, and high humidity significantly increase the risk. Left untreated, microbial growth can clog filters, foul injectors, corrode tanks, and lead to costly downtime.

Not all fuel contamination is biological in nature. Several other conditions are frequently mistaken for bacterial growth. Asphaltenes, which are heavy fuel components, can precipitate out of solution due to fuel incompatibility or oxidation, forming dark sludge. Paraffin wax crystals can form in cold temperatures, appearing as cloudy fuel or gel-like deposits. Rust and scale from steel tanks may also collect in filters and sumps, mimicking biological debris.

Unlike microbial contamination, these issues are not driven by water presence and require different corrective actions.

Gelled Diesel Fuel on Fuel Filter

Formation of paraffin wax crystals clogging a fuel filter - Untreated fuel is susceptible in frigid Canadian winters

Diagnosing contamination accurately is critical before treatment. Microbial contamination typically presents as dark, stringy, or gelatinous material with a sour or sulfur-like odor, often accompanied by rapid filter plugging. Laboratory fuel analysis or on-site test kits can confirm microbial presence and guide treatment decisions.

Microbial Contamination

Dark, stringy, or gelatinous material fished out of contaminated fuel

Several solutions exist to address diesel fuel contamination. For active microbial growth, the use of an effective diesel biocide is required to kill existing organisms. This should be followed by filter replacement and removal of water and dead biomass from the system. Fuel polishing and tank cleaning may be necessary in severe cases. For non-biological contamination, stabilizers, cold flow improvers, or fuel compatibility management may be more appropriate.

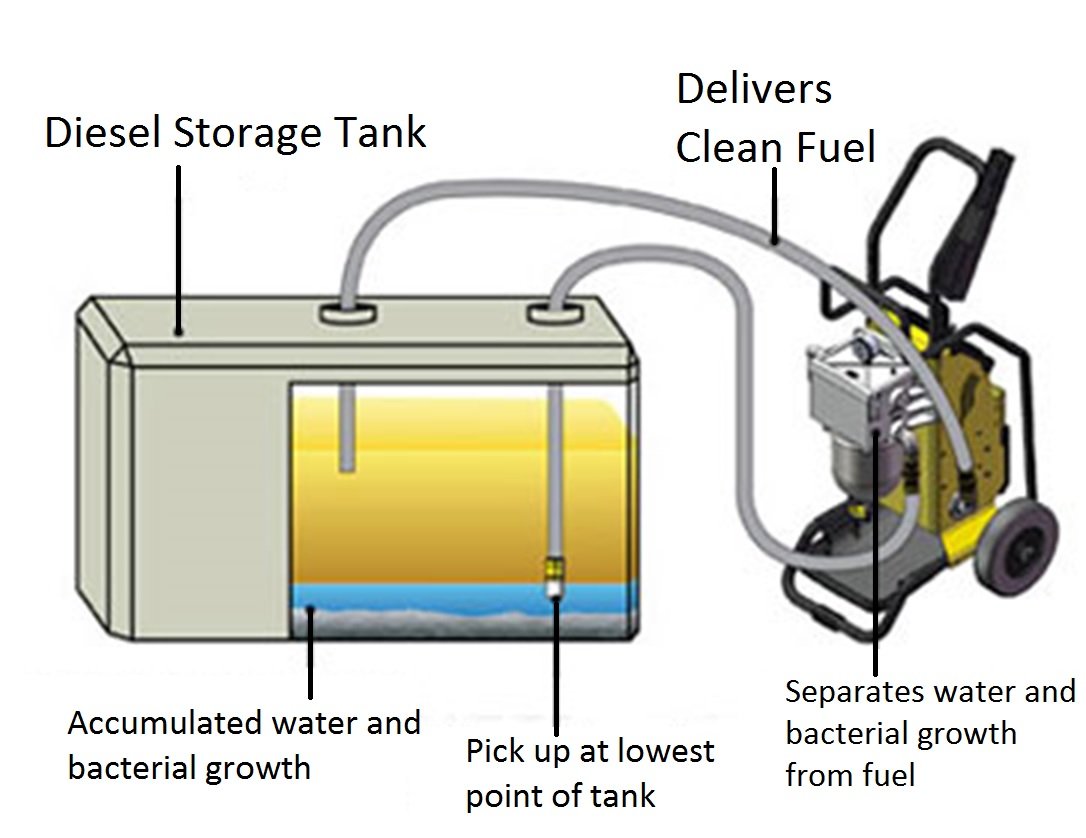

Fuel Polishing Diagram

How a fuel polishing system cleans fuel storage tanks to prevent costly repairs and keep your fuel “fresh”

Best practices focus on prevention rather than remediation. Maintaining dry tanks through regular water draining, proper tank ventilation, and sealed fill points is the single most effective defense. Regular fuel testing, tank inspections, and additive programs help extend fuel life and ensure reliability. Using a comprehensive fuel additive package, such as those offered by 4+ Fuel Additives, can improve fuel stability, manage water, inhibit corrosion, and reduce the risk of microbial growth when used as part of a disciplined fuel management strategy.

By understanding the true causes of diesel fuel contamination and applying the correct preventative measures, operators can protect their fuel assets, reduce maintenance costs, and ensure dependable performance when it matters most.